Municipal Applications

Drinking Water

Pretreatment, Solids Removal, & Clarification

Algae Removal:

Surface Water & Treatment Ponds

Solids Thickening

And More…

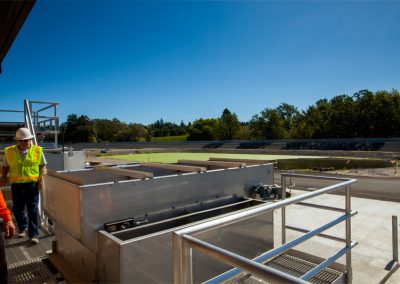

Municipal and Drinking Water Treatment with SAF®

Suspended Air® Flotation (SAF®) technology is deployed across municipal treatment facilities for a wide range of applications—from algae removal and landfill leachate treatment to solids thickening and advanced water clarification.

Key Applications:

-

Drinking Water Pretreatment – Removes algae, silt, and solids to extend filter cycles and improve plant efficiency

-

Algae Removal – Effective for seasonal blooms and high-turbidity surface water events

-

Solids Thickening – Thickens waste activated sludge (WAS) and anaerobic digestate with less energy and polymer

-

Clarification – Enhanced primary clarification, grit removal, and secondary clarification with thickening

-

Water Reclamation – Assists in meeting California Title 22 standards for reuse applications

-

Landfill Leachate – Treats complex waste streams with high solids and variable loads

Sustainable Advantages:

-

Low Energy Use – SAF® consumes a fraction of the power required by DAF, IAF, and other conventional systems

-

Reduced Chemical Demand – Requires significantly less polymer and conditioning agents

-

Compact Footprint – Modular, skid-mounted, and fully integrated systems eliminate the need for expansion/construction

-

Lower Emissions – Energy-efficient operation supports municipal GHG reduction goals

Whether for pretreatment, recovery, or discharge compliance, SAF® helps municipalities do more with less—while meeting today’s environmental and regulatory demands.

MUNICIPAL APPLICATION DOWNLOADS

To learn more about our Municipal Applications, see our downloads and specification table below.

MUNICIPAL TREATMENT APPLICATIONS

- Application

- Treatment Objectives

- City of Fortuna Wastewater Treatment Plant, Fortuna California

-

- Waste Activated Sludge Thickening

- Filtrate Treatment

- Enhanced Primary Clarification

- Synagro (Contractor for Sacramento Regional Wastewater Treatment Plant),

Sacramento California - Digester Solids Treatment

- Pleasant Valley State Prison

-

- Algae Removal from Holding Pond effluent

- Water Reclamation for Orchard Irrigation

- California Title 22 Compliance

- Graton Community Services District

-

- Algae Removal from Holding Pond effluent

- Water Reclamation for NPDES permit discharge

- California Title 22 Compliance

Heron Innovators, Inc., established 1998

The innovation behind Suspended Air® Flotation (SAF®) was invented by the late Dr. Felix Sebba in 1975. Since then, the engineering and science team at Heron Innovators has advanced this technology establishing flotation without dissolved air® as the next level in liquid/solid separation for water and wastewater treatment and solids thickening.

Since Heron Innovators is located in California's agricultural Central Valley, Suspended Air® Flotation (SAF®)'s first installations were in the food processing industry. Installations have expanded to other industries across the U.S., Mexico, and Canada. The SAF® process is applied anywhere physical/chemical separation via flotation is a viable solution to water quality. SAF® advances previous traditional process systems (i.e. dissolved air flotation, DAF, induced air flotation, IAF, Induced Gas Flotation, IGF, enhanced clarification, cavitation air flotation, CAF, and other micro-bubble generators) through flotation without dissolved air®.