SAF® Specifications and Products

| Horsepower | ||||||||||

| SAF® System | Flow Capacity | Float Area |

SAF® | Feed Pump |

Solids Pump |

|||||

| GPM | MGD | LPS | M3/D | BPD | Ft2 | M2 | ||||

| CF25 | 50 | 0.072 | 3 | 273 | 1,714 | 5.0 | 0.5 | 2.3 | 1.0 | 1.0 |

| CF50 | 125 | 0.180 | 8 | 681 | 4,286 | 10.0 | 0.9 | 2.3 | 2.0 | 2.0 |

| CF125 | 350 | 0.504 | 22 | 1,908 | 12,000 | 17.0 | 1.6 | 4.0 | 10.0 | 2.0 |

| CF250 | 700 | 1.008 | 44 | 3,816 | 24,000 | 35.0 | 3.3 | 6.3 | 15.0 | 3.0 |

| CF500 | 1,400 | 2.016 | 88 | 7,631 | 48,000 | 72.0 | 6.7 | 9.0 | 20.0 | 3.0 |

| CF1000 | 2,800 | 4.032 | 177 | 15,263 | 96,000 | 144.0 | 13.4 | 19.0 | 40.0 | 3.0 |

| CF2000 | 6,000 | 8.640 | 379 | 32,706 | 205,714 | 300.0 | 27.9 | 29.5 | 80.0 | 5.0 |

| CF3000 | 8,000 | 11.520 | 505 | 43,608 | 274,285 | 400.0 | 37.2 | 32.5 | 100.0 | 7.5 |

SAF® Generator Dimensions

| SAF® Generator | Base Size | Height w/ Cabinet |

Height w/o Cabinet |

| F25 | 34″ x 34″ | 78″ | 44 1/8″ |

| F50 | 46″ x 50 5/8″ | 76″ | 56 1/8″ |

| F100 | 48″ x 68″ | 74″ | 65 1/8″ |

| F200 | 54″ x 82″ | 77 1/2″ | 77 1/2″ |

| F400 | 78″ x 96″ | 86 1/8″ | 86 1/8″ |

SAF® Generator

The SAF® Generator produces microbubble froth independently of the process stream. These bubbles resist coalescing for significantly higher surface area and lifespan. Due to surface tension advantage and electrostatic affinity, the microbubbles attract, attach, and encapsulate the particles.

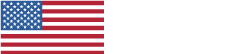

ClearFloater

SAF® systems do not require any additional air/gas to be injected into the flotation cell. Hydraulic and solids loading capacities are increased with SAF® due to rapid rise rates and a very robust float. Less surface area is needed for a smaller physical footprint. Heron offers stainless steel flotation cells for applications up to 11 MGD (42,000 M3/D).

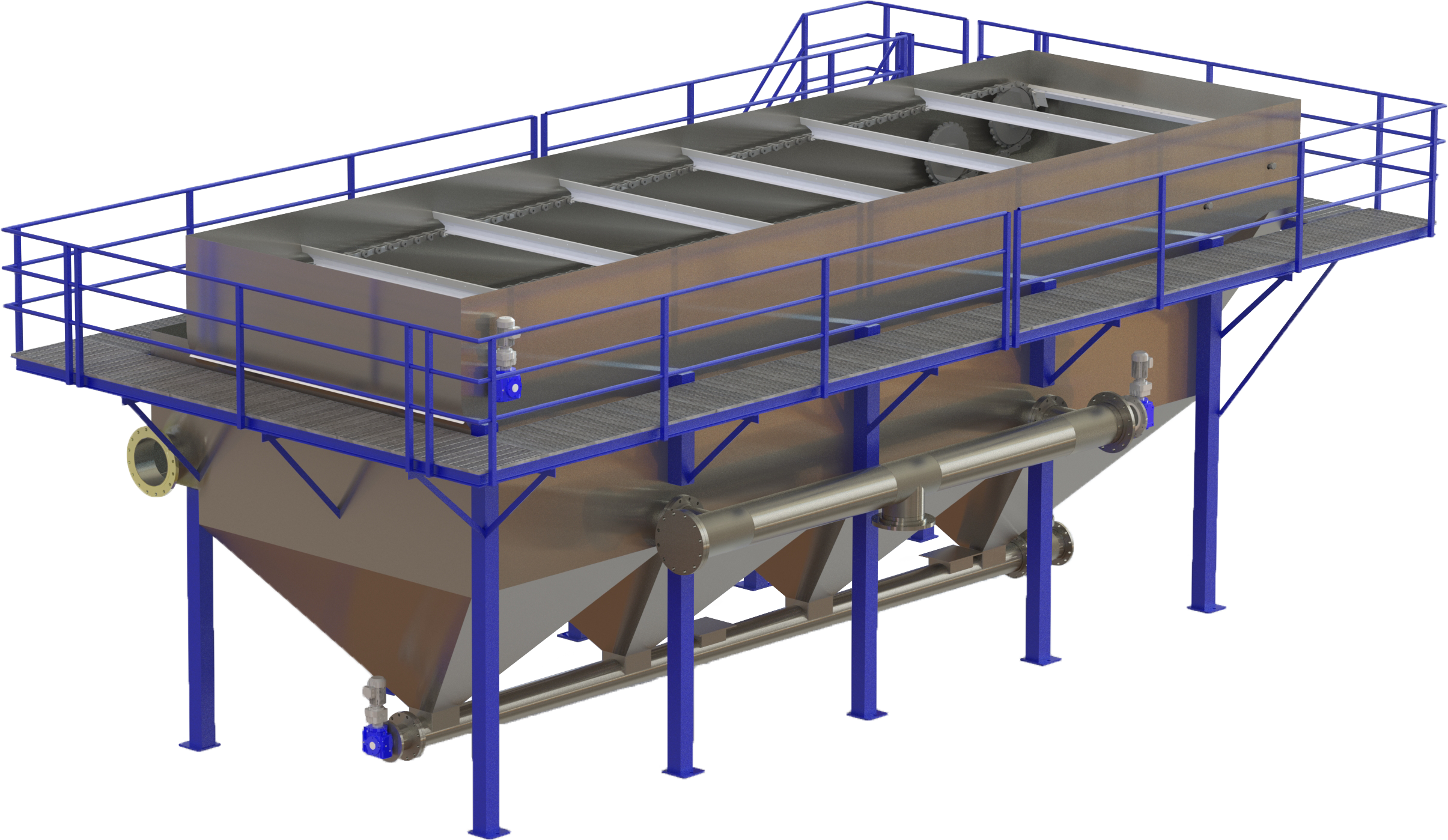

ClearMixer™

SAF® microbubble froth is injected and stirred into the influent stream prior to entering the flotation cell. Most of the microbubble to particle reaction takes place in this mixer.

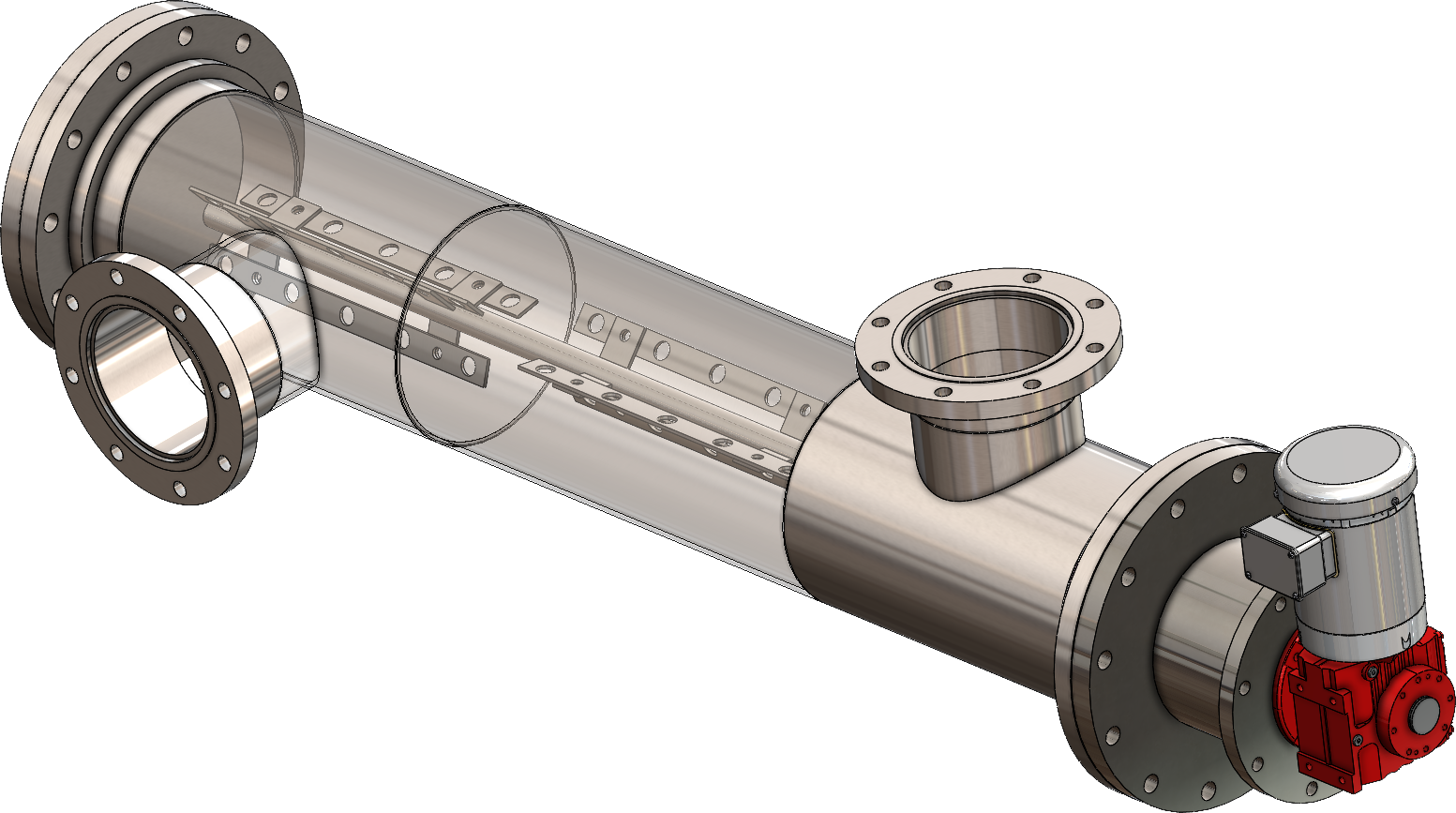

Skid Mounted Systems

Heron Innovators offers custom designed systems that are plumbed, wired, and tested with the flotation and ancillary equipment all on one single skid. This plug-and-play design minimizes installation time and costs normally associated with field integration of pumps, pH control, chemical feed, and other associated equipment. Commissioning and start-up are a matter of hours instead of days. Up to 4 MGD.

Heron Innovators, Inc., established 1998

The innovation behind Suspended Air® Flotation (SAF®) was invented by the late Dr. Felix Sebba in 1975. Since then, the engineering and science team at Heron Innovators has advanced this technology establishing flotation without dissolved air® as the next level in liquid/solid separation for water and wastewater treatment and solids thickening.

Since Heron Innovators is located in California's agricultural Central Valley, Suspended Air® Flotation (SAF®)'s first installations were in the food processing industry. Installations have expanded to other industries across the U.S., Mexico, and Canada. The SAF® process is applied anywhere physical/chemical separation via flotation is a viable solution to water quality. SAF® advances previous traditional process systems (i.e. dissolved air flotation, DAF, induced air flotation, IAF, Induced Gas Flotation, IGF, enhanced clarification, cavitation air flotation, CAF, and other micro-bubble generators) through flotation without dissolved air®.