THICKENING ACTIVATED SLUDGE WITH SUSPENDED AIR® FLOTATION (SAF®)

Summary of three case studies

PREPARED BY:

Harold Leverenz, Ph.D., P.E.

George Tchobanoglous, Ph.D., NAE, P.E.

Department of Civil and Environmental Engineering University of California, Davis,

Christina M. Skalko, P.E.

Short Elliott Hendrickson, Inc.

ABSTRACT

In the practice of wastewater treatment system design, process selection is often constrained by factors such as operational costs, performance, and physical footprint. Processes employing colloidal gaseous aphron (CGA) technology have proven to be highly effective for the clarification and thickening of activated sludge mixed liquor, waste-activated sludge (WAS), and anaerobically digested sludge within a small footprint. Technically, an aphron is defined as a gas or liquid phase encapsulated by a surfactant film. Since their initial identification and formulation, aphrons have been used extensively in a number of chemical processes, including gas and oil drilling and food processing waste-treatment applications. The generation and use of CGAs for thickening of WAS and other wastewater applications has been commercialized with the development of the Suspended Air® flotation (SAF®) process. The purpose of this paper is to (1) provide background on CGAs flotation technology, (2) identify applications of CGA in wastewater treatment, (3) discuss thickening of WAS with CGA, and (4) present findings from three case studies where WAS thickening with a legacy dissolved air flotation (DAF) process was replaced with a CGA process to increase capacity or address operational challenges, typically within the same flotation tank footprint. The case studies demonstrate the versatility of the SAF® CGA process for (a) its ability to process the most challenging feedstock, including stored WAS; (b) enhancement of the digestion process and elimination of digester foaming; and (c) high capacity and ease of operation, reducing operation needs.

Key Words

Colloidal gas aphrons, waste activated sludge, wastewater solids management

1. CGA FLOTATION TECHNOLOGY

Current aphron technology is based primarily on the research of Professor Frank Sebba, who worked on the formation of fine bubble aphrons under atmospheric conditions [1,2]. A detailed review of current research on apron applications as well as methods for generating aphrons was prepared by Molaei and Waters [3]. Technically, an aphron is defined as a gas or liquid phase encapsulated by a surfactant film. Fine bubble aphrons were first identified as micro foams or micro gas dispersions, but the term colloidal gas aphron (CGA) has been used more recently. High shear forces are required to generate the CGA suspension from a concentrated surfactant blend. One of the most striking observations was that the micron-sized CGA bubbles do not coalesce immediately if they are immersed completely in water and that when they collide, the momentum is not sufficient to break the encapsulating surfactant film. Based on these properties, CGAs have wide applications in the chemical process field, as well as in gas and oil drilling applications [3]. Additional details on these applications were developed by Sebba [4]. Wastewater applications of the CGA process are considered in the following section. The purpose of this work is to highlight systemic improvements that have been observed in wastewater treatment applications where conventional dissolved air flotation (DAF) has been replaced with SAF®.

2. APPLICATION OF THE SAF® PROCESS IN WASTEWATER TREATMENT

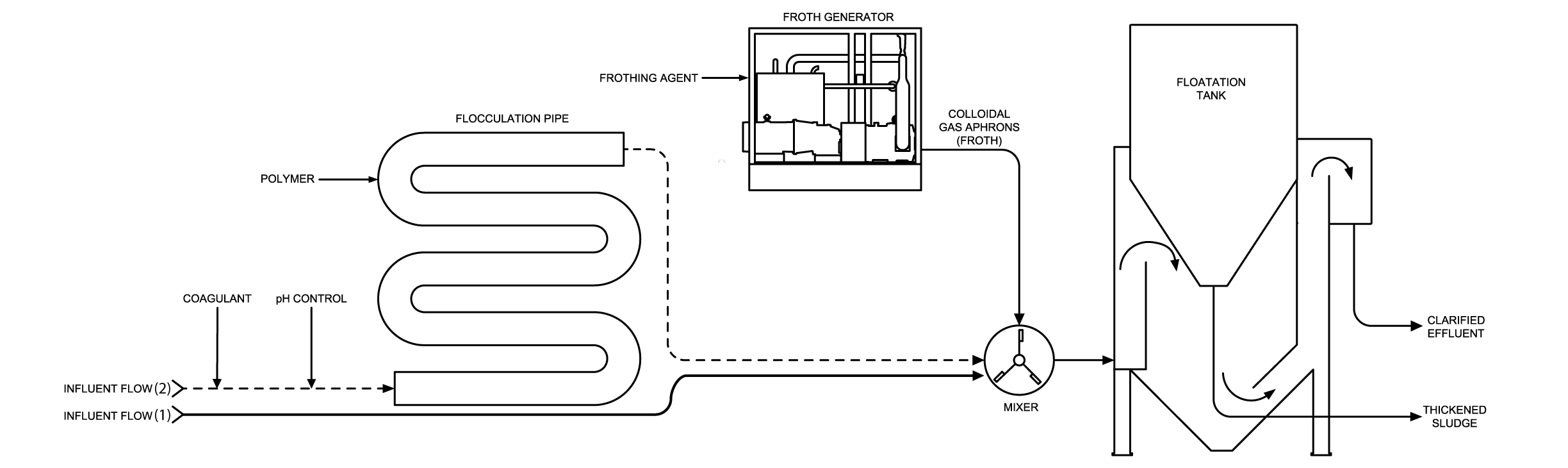

Flotation thickening and clarifying activated sludge mixed liquor using CGA suspension was first demonstrated by Enviro-Bubble Flotation, Inc. (EBF) of Sacramento, CA, USA, in October 1995 at the Red Bluff, CA, WWTP [5]. The current full-scale implementation of CGA clarification for wastewater applications has been commercialized by Heron Innovators Inc. (Roseville, CA, USA), and is known as the Suspended Air® flotation (SAF®) process. To date, the SAF® CGA process has principally been applied for the removal of algae from wastewater treatment pond effluents and for sludge thickening. In the treatment of pond effluent, it has been possible to achieve effluent turbidity values of 0.5 NTU or less. The SAF® process is used in a variety of other municipal wastewater applications, including primary treatment, filtration of filter backwash, and secondary clarification [6]. The principal components of the SAF® CGA process are illustrated in Figure 1. The SAF® process uses an externally generated suspension of micron-sized (about 7 to 25 µm) air bubbles. Each of the bubbles is coated with a thin film of an electrically charged chemically active surfactant such as a soap film, which may be either anionic or cationic, depending on the application. The surfactant film must have sufficient viscosity to remain stable when suspended in the bulk water and thereby minimize the Marangoni effect [3]. In water and wastewater applications, the volumetric air content typically ranges from 30 to 40 percent, compared with the estimated maximum of 5% achieved using DAF [5]. Because the CGA bubbles are either positively or negatively charged, they are readily attracted to oppositely charged wastewater solids that need to be removed. The wastewater particles are either naturally charged, such as negatively charged waste-activated sludge, or, alternatively, wastewater solids can be coated with charged polymer. Operationally, polymer solution is mixed with wastewater to form flocs and then the CGA suspension is intimately mixed with the flocculated solids before entering the flotation tank (see Figure 1). The flocculated solids buoyed by CGA then move to the flotation portion of the tank, where they float to the surface and are removed by skimming. Clarified underflow passes under a baffle and over a weir into the effluent launder. Once the CGA suspension is formed, the aphrons remain intact for approximately five minutes through the process of pumping, application to the flotation tank, and surface skimming. A few minutes after the solids have been skimmed from the surface, the aphrons collapse and become inactive.

Figure 1

The schematic flow diagram of the Suspended Air® Flotation (SAF®) process. Two modes of operation are possible, depending on the characteristics of the wastewater solids to be thickened: (1) without chemical flocculation, solid line, and (2) with chemical flocculation, dashed line.

3. THICKENING WASTE ACTIVATED SLUDGE WITH CGA

In typical activated sludge treatment process flow diagrams, as shown in Figure 2, WAS thickening can be used for the following purposes: (1) to thicken waste mixed liquor (see Figure 2a) or (2) alternatively, to thicken settled activated sludge (see Figure 2b). In either case, the rationale for thickening is to increase the solids concentration of the WAS by reducing the liquid volume. Where anaerobic digestion is used, thickening of WAS is used (1) to improve process performance, typically gas production, by increasing the solids retention time and (2) to enhance the digestion process stability by reducing the liquid volume of the digester feed. Several alternative thickening processes are used to thicken WAS, including gravity thickening, a belt filter, and DAF.

Figure 2

Alternative configurations for secondary sludge wasting: (a) from aeration tank and (b) from secondary clarifier. Note that the primary clarifier may not be present in some cases. Adapted from Tchobanoglous et al., 2014.

4. CASE STUDIES

The SAF® process has been evaluated for thickening of WAS in numerous installations and, in all cases, the SAF® process has been demonstrated to provide consistent high performance and reliable operation. Comparison of the SAF® and DAF process for WAS thickening is best exemplified by three recent case studies [8,9,10] presented in this section, in which the SAF® process was used to replace and upgrade an existing DAF facility. The use of CGA has allowed for significant improvements in TSS removal, capacity, operational time, operational cost, and solids management.

Topeka, KS (Oakland Wastewater Treatment Facility)

A recent case study on WAS thickening at Topeka, KS, was summarized by Tchobanoglous et al. [11]. The total solids content of WAS at the Oakland WWTP varies considerably, depending on the operation of biological reactors and clarifiers. The SAF® process was evaluated at the Oakland WWTP to replace legacy DAF units for thickening prior to anaerobic digestion to increase the solids content of WAS. For example, WAS pumped from secondary settling tanks containing 0.4 to 0.8% solids was thickened to 4% solid content, resulting in a five-fold decrease in sludge volume and a corresponding increase in digester retention time. In addition to achieving high WAS solids separation efficiency, based on onsite testing, the principal advantages of the SAF® process include a relatively small process footprint, low power requirement, low chemical usage, and the ability to handle both aged/stored sludge and high concentrations of suspended solids (up to 16,000 mg/L in this study).

Table 1

Summary of representative pilot test performance for SAF® operating on WAS combined with stored WAS (Pilot test, October 2020) at the Oakland WWTP in Topeka Kansas.a

|

Influent TSS, mg/L |

Effluent TSS, mg/L |

Removal, % |

Float TS, % |

Liquid flowrate, gal/min |

Aphron flowrate, gal/min |

Loading, lb/ft2·h |

Polymer, lb/dry ton |

|

8800 |

57 |

99.4 |

5.4 |

80 |

3.2 |

20.1 |

1.3 |

|

8390 |

33 |

99.6 |

7.3 |

85 |

3.5 |

20.4 |

1.3 |

|

6980 |

461 |

93.4 |

7.0 |

140 |

7.0 |

27.9 |

2.8 |

|

4650 |

ND |

100 |

6.3 |

95 |

3.8 |

12.6 |

6.0 |

|

9250 |

ND |

100 |

6.6 |

92 |

3.8 |

24.3 |

3.0 |

|

15,700 |

ND |

100 |

7.5 |

90 |

4.3 |

40.4 |

1.8 |

|

8860 |

20 |

99.8 |

5.9 |

138 |

8.2 |

35.0 |

5.1 |

a Data courtesy Zeller (2023).

Warminster, PA (Warminster Municipal Authority)

The Warminster case study highlights the potential impacts of improved thickening process performance on downstream solids processing. Prior to installation of the SAF® process at the Warminster facility, a legacy DAF process had been used to thicken WAS prior to anaerobic digestion. The DAF process typically produced thickened solids in the range of 3.5 to 4.5%. The low concentration of solids in the thickened WAS directly impacted the solids retention times (SRTs) in the anaerobic digesters. Also, during operation with DAF, periodic digester foaming events occurred due in part to mixing limitations within the existing digesters and the SRT variations resulting from thickening process control. Digester foaming is commonly associated with anaerobic process overloading and operational imbalances at reduced or fluctuating SRTs.

Figure 3. Process data comparing DAF and SAF® at Warminster, PA, revealed the following findings: (a) improved thickening before digestion, (b) adaptation to variable WAS flows during low-flow drought conditions, red data = WAS flow, blue data = waste TS, (c) improved retention time and alkalinity buffer development in digesters (note that uneven transfer of thickened WAS to digesters 3 and 4 resulted in a greater SRT in digester 3), and (d) more consistent centrifuge feed, resulting in a reduced centrifuge runtime, red = solids flow, blue = feed %TS. These data were provided by Krauss [9].

Sauk Centre, MN (Sauk Centre Wastewater Treatment Facility)

The WWTF at Sauk Centre receives primarily domestic wastewater and has a typical flowrate of 0.43 Mgal/d. The WWTF consists of a fine screen (Huber Technology, Denver, NC), grit removal (Pista, Smith & Loveless, Lenexa, KS), an activated sludge process (Short Elliott Hendrickson, Inc., St. Paul, MN, USA), UV disinfection (Trojan Technologies, London, ON, Canada), and WAS thickening (Heron Innovators). Thickened waste solids are stored in a 1.2 Mgal vessel for seasonal land application. The SAF® process was brought in to replace an overloaded DAF process. Considerations for the DAF replacement included the following requirements:

-

The replacement should meet or exceed the required capacity, which is equivalent to 96,000 gal/d.

-

It should fit within the existing DAF footprint, with an existing tank measuring 60 ft2.

-

The operational costs (e.g., the cost of the polymer, operator time, and electricity) should be equivalent or lower.

Table 2

Comparison of DAF and SAF® processes at Sauk Centre Wastewater Treatment Facilitya

|

Parameter |

Unit |

DAF |

SAF |

SAF® difference |

|

Area |

ft2 |

60 |

60 |

– |

|

Loading rate |

gpm |

13 |

75 |

+ 500% |

|

Operational time |

1/wk |

24 h/d x 7d |

7 h/d x 4.5 d |

– 80% |

|

TS |

% |

4.1 |

4.7 |

+ 15% |

|

Polymer use |

gal/wk |

10.5 |

4.6 |

– 60% |

|

Surfactant use |

gal/wk |

0 |

2.8 |

|

|

Biosolids volume |

Mgal/y |

1.14 |

0.96 |

– 15% |

a Data Courtesy Bauer (2024)

5. DISCUSSION

Author Contributions

Conceptualization, H.L. and G.T.; writing—original draft preparation, H.L. and G.T.; field data collection, C.M.S.; writing—review and editing, H.L., G.T. and C.M.S. All authors have read and agreed to the published version of the manuscript.

Funding

Data Availability Statement

ACKNOWLEDGMENTS

Conflicts of Interest

REFERENCES

- Sebba, F. Microfoams—An Unexploited Colloid System. J. Coll. Interface Sci. 1971, 35, 643–646. [Google Scholar] [CrossRef]

- Sebba, F. Foams and Biliquid Foams—Aphrons; John Wiley and Sons: New York, NY, USA, 1987. [Google Scholar]

- Molaei, A.; Waters, K.E. Aphron Applications—A Review of Recent and Current Research. Adv. Colloid Interface Sci. 2015, 216, 36–54. [Google Scholar] [CrossRef] [PubMed]

- Sebba, F. Separations Using Aphrons. Sep. Purif. Methods 1985, 14, 127–148. [Google Scholar] [CrossRef]

- Adams, R.M. (Advanced Organic Methods Inc., Penryn, CA, USA). Personal communication. 2024.

- Tchobanoglous, G.; Leverenz, H. Versatility of the SAF® Process in Municipal Wastewater Treatment Systems. Department of Civil and Environmental Engineering, University of California Davis: Davis, CA, USA, 2024; in preparation. [Google Scholar]

- Tchobanoglous, G.; Stensel, H.D.; Tsuchihashi, R.; Burton, F.L. Wastewater Engineering: Treatment and Resource Recovery, 5th ed.; McGraw-Hill Book Company: New York, NY, USA, 2014. [Google Scholar]

- Zeller, D. (Water Pollution Control Division, City of Topeka, KS, USA). Personal communication. 2023.

- Krauss, R. (Warminster Municipal Authority, Warminster, PA, USA). Personal communication. 2024.

- Bauer, G. (Sauk Centre Wastewater Treatment Facility, Sauk Centre, MN, USA). Personal communication. 2024.

- Tchobanoglous, G.; Leverenz, H.; Zeller, D. Application of the Suspended Air® Flotation (SAF®) Process for Thickening of Waste Activated Sludge (WAS). Water Environ. Technol. 2022, 6, 36–41. [Google Scholar]