Suspended Air® Flotation for Algae Control | TPO Magazine | April 2022

Ready for the Field

Ready for the Field

A SUSPENDED AIR FLOTATION PROCESS HELPS THE CALIFORNIA DEPARTMENT OF CORRECTIONS CONQUER AN ALGAE PROBLEM AND PRODUCE HIGH-VALUE TITLE 22 WATER FOR FARM IRRIGATION

By David Bachtel, PE, BCEE

The California Department of Corrections wanted to produce highly marketable Title 22 tertiary effluent from wastewater at its Pleasant Valley State Prison at Coalinga. Meanwhile, a neighboring farmer wished to convert a 135-acre irrigated site from forage crops to higher-value pistachio orchards that require tertiary-treated effluent. The district successfully produced the necessary water quality by adding a Suspended Air Flotation process (Heron Innovators) followed by dual-media filtration to its aerated lagoon secondary treatment facility on the prison site.

EXPLORING ALTERNATIVES

Wastewater from the prison is treated in a O .65 mgd aerated pond; the disinfected secondary effluent was being stored on site and used for flood irrigation at the farm. The farmer’s contract for receiving the effluent was up for renewal, and the department wanted to produce the Title 22 tertiary effluent to maximize its value in times of drought. Initial studies recommended the use of cloth disc filtration followed by upgraded effluent chlorination.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

However, a review by the Regional Water Quality Control Board and the state Department of Dr inking Water, responsible for permitting the facility, questioned the feasibility of direct filtration of the secondary effluent due to the possibility of algal growth in the aerated ponds during summer.

Subsequent studies indicated that up to 60 ppm of algae could be present in the pond effluent, so that a pretreatment step for algae removal before filtration would be needed to avoid a replacement of the ponds with activated sludge treatment.

SAF turbidity removal was extremely high; effluent consistently averaged 0.45 NTU for the first six days of the test, while the filter effluent turbidity averaged 0.78 NTU.

The department did not have the time or budget to perform pilot studies. A comprehensive review of algae removal technologies identified a facility in the small northern California town of Grat on was successfully using Suspended Air Flotation (SAF) to remove algae from long-residence-\ ime aerated pond secondary effluent. Accordingly, the department chose the SAF process in conjunction with dual-media filtration to produce the Title 22 reuse water.

BUILDING THE PROCESS

The prison influent had a BODs of 70-410 mg/L with an average of 130 mg/L, TSS was 13-20 mg/L, and total nitrogen was 60-70 mg/L. Floating surface aerators provided a minimum dissolved oxygen of 1.0 mg/L, and the lined aeration pond detention time was up to 40 days at average design flow.

The four ponds, operated in series, were modified to allow storage by varying water levels to obtain up to seven days of storage in the event of process upset. The gravity flow from the last pond was modified for pumped flow, allowing continuous flow to the tertiary treatment process. This minimized equipment capacity and allowed the use of storage instead of redundancy to minimize capital cost.

The tertiary process included a pump station to feed a packaged SAF unit installed at grade at an adjustable, constant flow rate, gravity flow to a three-cell dual-media gravity sand filter, discharge of filtered effluent through a backwash storage well, and discharge to two chlorine contact tanks before to storage ponds.

Interruptions in the tertiary process affecting permit compliance (equipment failure, excess turbidity or inadequate chlorine residual) would result in shutdown of pumping to the process and accumulation of flow in the treat-ment ponds. In case of an extended shutdown, on-site storage ponds provided 90 days of secondary effluent storage.

THE SAF PROCESS

The SAF unit is similar to dissolved air flotation, with one major difference. Instead of saturating a large return flow of water at high pressure and then releasing the pressure to form fine bubbles as the dissolved air is released from the solution, the SAF unit creates bubbles (aphrons <10 microns) using a froth generator.

The froth generator uses a small flow of water that, when combined with a frothing agent (surfactant), produces very fine bubbles with surface charge characteristics defined by the type and amount of surfactant added.

The froth, solids to be removed, flocculant and coagulant are combined in a flocculator to form a stable complex of fine bubbles and solids that is less dense than water and so concentrates on the surface of a separation tank (clarifier) for drainage and removal. The solids are skimmed from the clarifier surface and pumped for further thicken ing/dewatering.

The selection and use of the frothing agent allows the process to be opt imized for the surface charge characteristics of the solids to be removed. Solids (primarily algae) collected by the SAF unit at the prison are further treated with polymer to enhance water release. The sol ids are then pumped to roll-off containers fitted with drainage grids supporting geotextile bags for gravity dewater ing before landfill.

Multiple containers are used. Two containers are alternated daily, receiving solids from the SAF unit; a third container undergoes final drainage before landfilling. Sol ids removed during tertiary filter backwash are returned to the head of the aeration tanks.

START-UP AND PERFORMANCE TESTING

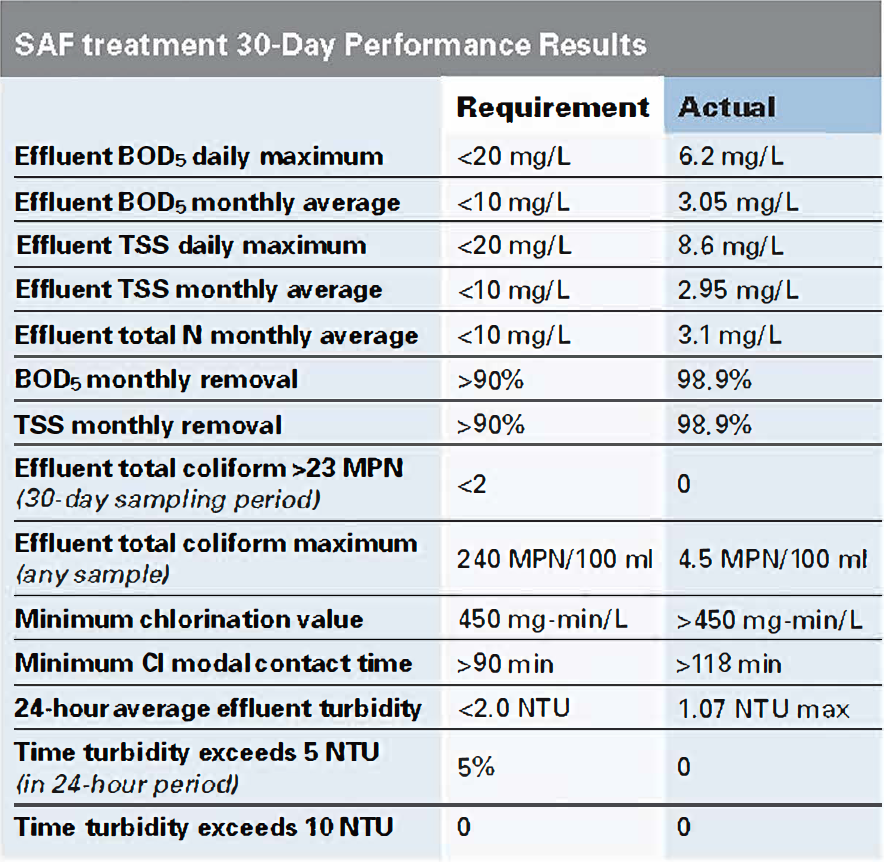

Title 22 for disinfected tertiary effluent requires:

- Effluent to tertiary filters not to exceed 5 NTU for more than 15 minutes at at ime or 10 NTU at any time

- Effluent from the tertiary filters not to exceed 2 NTU 24-hour average, 5 NTU for 5% of the time with in 24-hour period, or 10 NTU at any time

Performance testing was conducted continuously from Nov. 1-30, 2020, during which the facility was operated by prison staff without assistance. During testing, the facility met all discharge permit requirements.

On Nov. 7, the filter influent turbidity meter sensor failed, apparently because of exposure to concentrated hypochlorite solution from a filter prechlorination connect ion in the filter feed piping upstream of the sensor. The data from the period through Nov. 6, was consistent with the SAF effluent/filter feed turbidity regularly experienced before the test period.

SAF turbidity removal was extremely high; effluent consistently averaged 0.45 NTU for the first six days of the test, while the filter effluent turbidity averaged 0.78 NTU. It is suspected that the measured increase in turbidity after filtration may be the result of biological growth in the filter media.

Reviewing filter effluent turbidity from individual cells as well as the filter as a whole, consistent effluent turbidity from the individual filter cells and the tertiary process as a whole was consistently well below 2 NTU. When the system is operating continuously, the filter cells are typically backwashed every other day due to the low solids loading.

ABOUT THE AUTHOR

David Bachtel is vice president of Bachtel Wastewater Engineers in Sisters, Oregon.

Download The Original Text

Fill out the form to download the full text as printed in TPO Magazine.