SAF®

TURN-KEY RENTAL SYSTEMS

For Water and Wastewater Applications

Suspended Air® Flotation (SAF®)

Heron Innovators offers a comprehensive fleet of SAF® pilot and rental systems, including the CF50, CF125, CF250, and CF500 skids, as detailed in the specifications table. These systems are engineered to treat flows ranging from 50 to 1400 GPM, providing versatile solutions for industrial and municipal water treatment applications.

Specifications

- Materials: AISI Type 304 stainless steel, PVC, and polyurethane construction.

- Flow Capacities: Systems accommodate flow rates from 50 to 1400 GPM and can be equipped with pH control systems utilizing PID loops.

- Customization: Designed to meet specific customer requirements while maintaining Heron Innovators’ rigorous product standards.

Pilot Testing Capabilities

Heron Innovators provides pilot-scale testing to validate process performance and operating costs, building on results from laboratory analyses.

Treatability Studies

- Laboratory Testing: Jar tests to determine optimal polymer and flocculent dosing, as well as pH adjustments.

- Analytical Insights: Comprehensive results to predict process performance and operating costs.

Optional Features

- Feed Pump: Self-priming pump with variable frequency drive (VFD) controller.

- Flow Meter: 4-inch magnetic flow meter for precise monitoring.

- pH Control System: PID loops for acid and caustic feed regulation.

- Coagulation Control: Flow-controlled outlets for coagulant feed and serpentine-style floc mixers.

- Polymer System: Dosing, flash mixing, and polymer aging system.

- Working Tanks: Designed for conditioning chemistry.

- Flotation Cell: Equipped with SAF® froth generation technology.

- Solids Pump: Positive displacement pump for skimmed solids handling.

Demonstrated System Capabilities

- Primary influent clarification as a replacement for primary clarifiers.

- Treatment of overflow pond return water containing algae or partially digested raw influent.

- Clarification of activated sludge mixed liquor, with concurrent MLSS thickening.

- Clarification of digested sludge belt filter press filtrate and wash water.

System Capabilities and Services Provided

- Engineering Design: Comprehensive process and component design.

- Fabrication: Custom stainless steel tanks and components.

- Technical Drawings: 2D and 3D designs using SolidWorks and AutoCAD for mechanical and electrical fabrication.

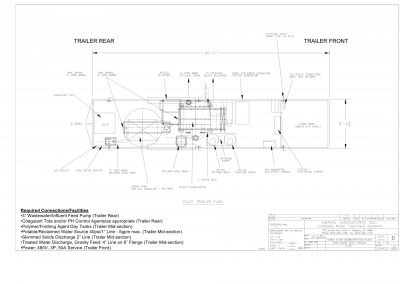

- Pilot Operation: Turnkey pilot trailer provision and operation.

- Fast Start-Up: Starts up in hours, not days.