by jason | Aug 18, 2021

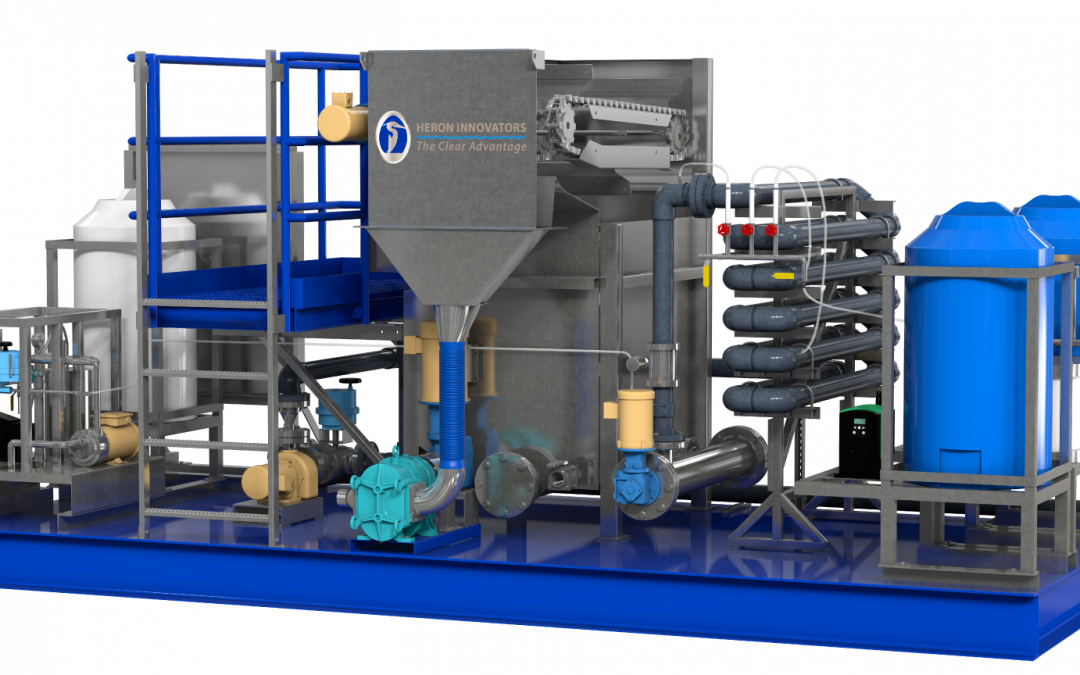

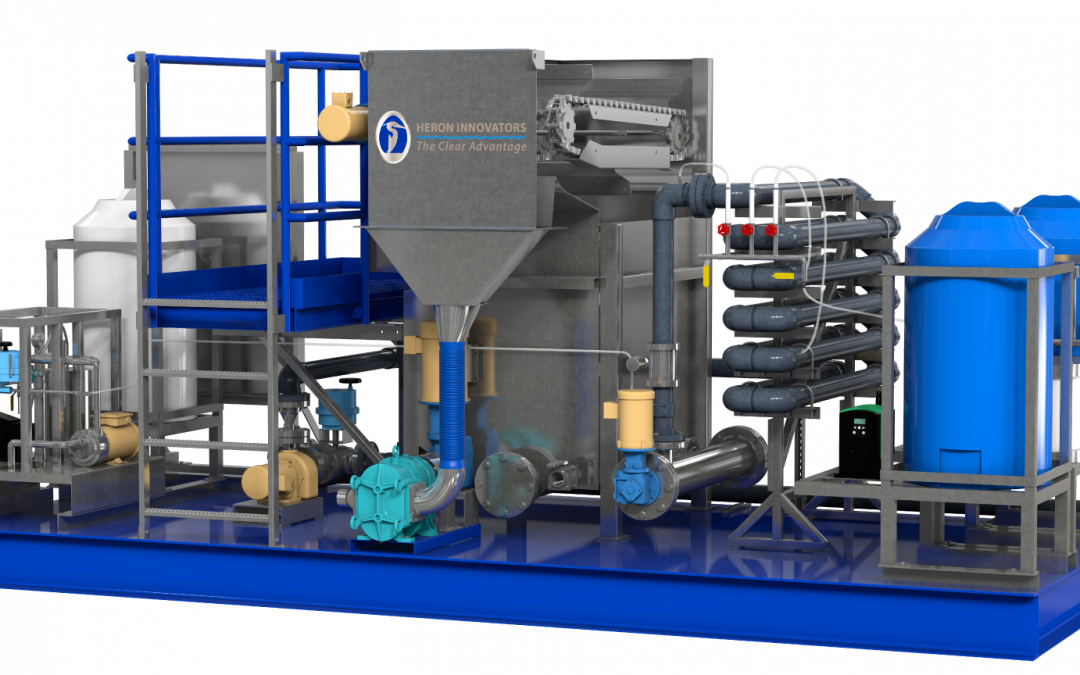

This 3D render of a Skid-Mounted SAF® Water Treatment System

by jason | Aug 18, 2021

Heron Innovators

10624 Industrial Avenue, Roseville, CA 95678

Tel: 916.408.6601 Fax: 916.408.6991

Email: [email protected]

Business Hours

Monday – Friday | 6am – 3pm

Recent Comments